Understanding Grounding in Photovoltaic Power Systems for Enhanced Safety and Efficiency

- 04/07/2024

Discover the indispensable role of proper grounding in photovoltaic systems. Learn how it mitigates risks from electric shocks to lightning strikes, ensuring both personnel safety and system reliability.

The Importance of Grounding

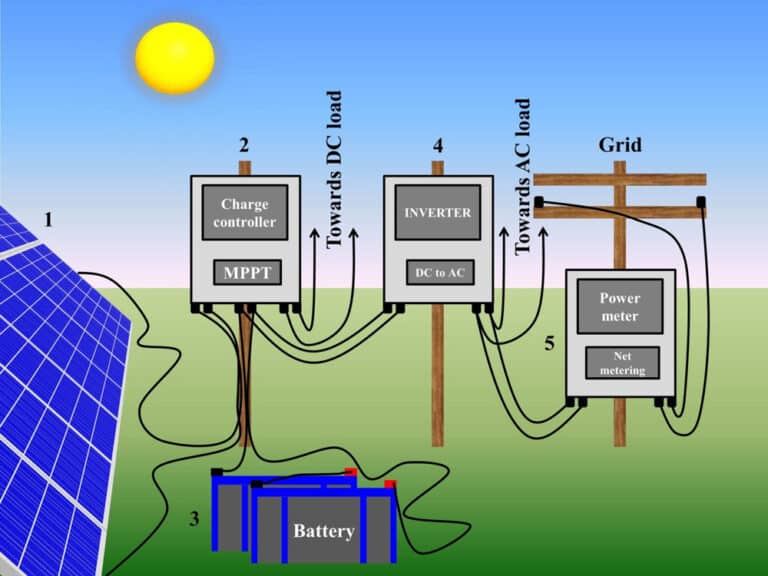

Grounding plays a pivotal role in safeguarding electrical setups, especially in photovoltaic power stations. It’s the method of electrically connecting the neutral point of a power system, including various installations and the conductive elements of electrical equipment directly to the earth through grounding conductors.

The Importance of Grounding

Why Is Grounding Essential?

- 1.Preventing Electric Shock

The impedance of the human body can change with environmental conditions, such as humidity. Grounding helps in reducing this variable impedance to stabilize it by equating the potential energy of the electrical apparatus with that of the ground. This greatly reduces the chances of potential electric shocks in the event of a fault. - 2.Ensuring Power System Operation

The grounding, often referred to as work grounding, is critical at the neutral points typically situated within substations. It necessitates a very low resistance to grounding, usually enabled through an extensive grounding network. Its importance can’t be overstated as it aids in maintaining a stable potential of the power grid’s neutral with respect to the earth. - 3.Protecting Against Lightning and Static Electricity

Utilizing grounding as a safeguard against lightning and static electricity is a norm. It serves as the conductive path for the unnatural high voltage to safely enter the earth, thereby protecting both personnel and apparatus.

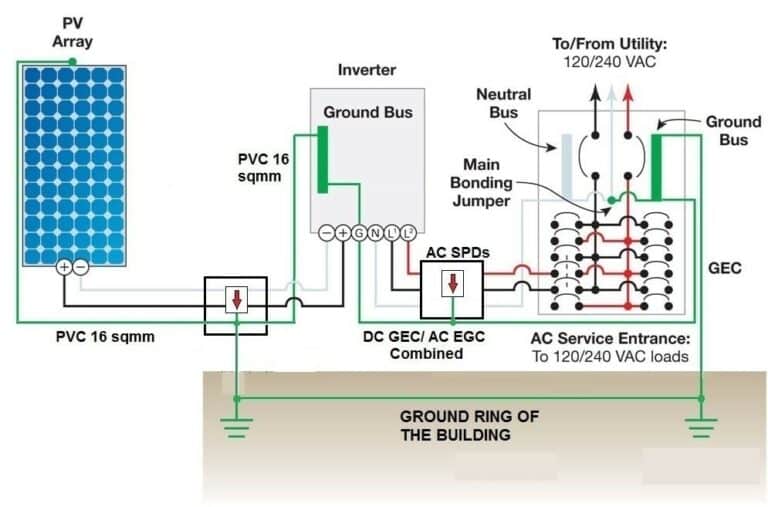

(PV grounding diagram for 120/240V split phase solar system)

Understanding the Category of Grounding

Lightning Protection Grounding: A protective measure earmarked for equipment and structures, diverting a strike directly into the ground using arresters.

AC Work Grounding: Important for power system stabilization, it connects the transformer’s neutral point or line directly to the earth.

Safety Protection Grounding: Ensures that non-energetic metallic parts of electrical equipment are safely connected to the ground.

Shield Grounding: Deployed to prevent electromagnetic disruptions, particularly with shielded communication lines.

Anti-Static Grounding: Vital in preventing electrostatic buildup, often used in dry environments like server rooms.

(The inverter shell is grounded)

Description

Requirements

Lightning protection grounding

≤ 10 ohms grounding resistance

Safety protection grounding

≤ 4 ohms grounding resistance

AC work grounding

≤ 4 ohms grounding resistance

DC work grounding

≤ 4 ohms grounding resistance

Anti-static grounding

≤ 100 ohms grounding resistance

Shared ground boday

Resistance lower than the required grounding standard

Best Practices for Effective Grounding

- Perform comprehensive site assessments to determine the unique grounding requirements.

- Opt for high-conductivity, durable grounding materials.

- Enforce regular inspections and maintenance for enduring efficacy.

Examples of photovoltaic systems that have successfully mitigated risks from electric shocks and lightning strikes through grounding.

- 1. Large-scale Solar Farms: Commercial solar farms often have extensive grounding systems with grounding rods driven deep into the earth. These systems are engineered to meet specific soil resistivity, ensuring effective dissipation of fault currents and lightning surges. Their success in mitigating risks can usually be seen by the continuous operation of these farms even after local lightning storms.

- 2. Building Integrated Photovoltaic Systems (BIPVs): BIPVs, which are integrated into the building structure, often make use of the structural grounding systems. These are specially designed to handle lightning strikes by providing a low-resistance path to ground. The successful operation of BIPVs in high-rise buildings, which are prone to lightning strikes, is partly due to these grounding measures.

- 3. Residential Solar Installations: In residential environments, PV systems are generally required to comply with national electrical codes, which include grounding and bonding requirements. Anecdotal evidence from homeowners and installation companies suggest that adherence to these codes has effectively prevented electrical incidents even when installations are struck by lightning.

- 4. Off-grid PV Systems:With the increased use of PV systems in remote locations, grounding becomes even more vital. Systems deployed in such settings, including telecommunications repeaters or remote sensor arrays, often incorporate grounding in their design and have demonstrated resilience to electrical events.

- 5. Solar Parking Canopies and Carports: These structures integrate PV modules and are exposed to the elements. They employ robust grounding systems which are crucial for mitigating potential lightning strike damage. Successful mitigation is evidenced by the fact that these structures tend to sustain operations without disruptions, even in regions frequent lightning storms.

- 6. Ground-Mounted PV Systems: These systems have grounding systems designed to cater specifically to their exposure to environmental electrical risks. The success of these designs is seen in the minimal disruption to service despite ground-mounted systems’ high exposure to lightning strikes.

What other safety measures are commonly implemented in photovoltaic systems to mitigate risks

- 1. Surge Protection Devices (SPDs): SPDs are used to protect the electrical components of PV systems from transient voltage spikes often caused by lightning or power surges. They work by diverting the excess voltage away from the sensitive components of the system.

- 2. Fuses and Circuit Breakers: These protective devices are designed to cut off the electrical supply in case of overcurrent, which can occur due to faults or equipment overloads.

- 3. GFCIs (Ground Fault Circuit Interrupters): GFCIs are designed to protect against electric shocks by quickly disconnecting the power if a ground fault is detected.

- 4. Arc Fault Circuit Interrupters (AFCIs): AFCIs are used to protect against electrical fires by shutting down the system in the event of an arc fault, which could otherwise cause overheating and ignite flammable materials.

- 5. PV Wire and Cable Insulation: Use of quality, sunlight-resistant, and temperature-rated insulating materials for wiring to prevent degradation, shorts, and potential fire hazards.

- 6. Rapid Shutdown Systems: These systems enable the de-energization of the PV panels and components to a safe voltage level within seconds, protecting first responders and anyone else who might come into contact with the system during an emergency.

- 7. Fire Safety Measures: Including fire-rated materials for panels and barriers, spacing between panels on roofs to impede fire spread, and compliance with fire codes.

- 8. Labeling and Signage: Proper labeling of electrical components and power sources as per industry standards to communicate potential hazards and ensure that maintenance personnel are aware of the points of isolation.

- 9. Panel Racking and Mounting Systems: Engineered to withstand environmental loads such as wind, snow, and seismic activities, ensuring that panels remain securely fastened.

- 10.Technician Training and Access: Ensuring that installation and maintenance technicians are well-trained on the specific PV system’s safety features and risks. Designing the system for safe access for periodic maintenance can prevent accidents.

- 11.Regular Inspection and Maintenance: Regularly scheduled inspections and maintenance of the system can help identify and remedy potential issues before they become hazards.

- 12.Protection from Rodents and Environmental Damage: Use of conduits and other protective measures to prevent damage by rodents or environmental factors that can lead to exposed wires or faulty connections.

How do Surge Protection Devices (SPDs) work to protect electrical components in photovoltaic systems?

Surge Protection Devices (SPDs) are critical components that protect electrical systems, including photovoltaic (PV) systems, from voltage transients, commonly known as surges. Surges can be caused by lightning strikes, power grid switching, or malfunctions in other equipment connected to the power system. Here’s how SPDs work to safeguard PV systems:

- 1. Detection of Voltage Surges:

- SPDs are constantly monitoring the voltage levels in the electrical circuit.

- When the voltage exceeds a predefined threshold, which is beyond the normal operating voltage, the SPD recognizes this as a surge.

- 2. Diversion of Surge Current:

- Upon detection of a surge, the SPD acts by creating a low resistance path for the excess current.

- The device quickly channels the surge current safely to the ground, away from the sensitive components of the PV system.

- 3. High-speed Response:

- SPDs respond almost instantaneously to voltage surges. The time it takes for an SPD to react is crucial to its effectiveness and is typically measured in nanoseconds.

- This swift action is necessary to ensure that the surge is dealt with before it can cause any damage to the PV equipment.

- 4. Utilization of Varistors or Gas Discharge Tubes:

- Metal Oxide Varistors (MOVs) and Gas Discharge Tubes (GDTs) are common components within SPDs.

- MOVs can clamp high voltage surges, reducing them to safer levels by changing their resistance.

- GDTs work by ionizing the gas inside the tube under high voltage conditions, creating a conductive path that diverts the surge to the ground.

- 5. Restoration to Normal Operation:

- After the transient voltage is safely diverted, the SPD resets itself, exhibiting high resistance, and allows the PV system to continue operating under normal voltage conditions.

- Some SPDs have indicators or alarms to signal that a surge event has occurred or if the SPD has been compromised and needs replacement.

- 6. Layers of Protection:

- Effective surge protection often involves multiple layers (or stages) of SPDs arranged at different points in the system, from the main service entrance to individual branches.

- These cascaded SPDs ensure that any surges not fully clamped by one device are further reduced by subsequent ones closer to the sensitive equipment.

By absorbing or diverting the dangerous surges, SPDs help to extend the operational life of the PV system, reduce maintenance costs, and prevent system outages. They’re an essential element in protecting both the investment in the photovoltaic system and its safe operation.

What are some common types of Surge Protection Devices (SPDs) used in photovoltaic systems?

In photovoltaic (PV) systems, several common types of Surge Protection Devices (SPDs) are used to shield the electrical equipment from surges. These types include:

- 1. Type 1 SPDs:

- These are designed to protect against large surge events, primarily lightning strikes.

- Usually installed at a service entrance.

- Type 1 SPDs are characterized by their ability to handle very high surge currents and are typically used in areas prone to direct lightning strikes.

- 2. Type 2 SPDs:

- Intended to protect against residual surges that might get past the Type 1 SPDs or surges from equipment on the utility side.

- Installed at branch panels or equipment level, they shield against the surges that occur within a facility.

- They are recognized for their role in protecting against the high-energy transients that can occur as a result of switching transients and indirect lightning.

- 3. Type 3 SPDs:

- Offering fine, localized protection, Type 3 SPDs protect individual devices.

- Typically installed in close proximity to the equipment they’re designed to protect, such as inverters, control panels, or monitoring systems.

- They help defend against lower-energy events that may have traversed the electrical system and cope with surges arising from switching and other disturbances.

- 4. Combination SPDs:

- A combo SPD is designed to offer both Type 1 and Type 2 protections in a single unit.

- It’s a comprehensive protection solution suitable for various points within the PV system, providing flexibility in surge protection design.

- 5. DC SPDs:

- Direct Current (DC) SPDs are intended for the DC side of the PV system, typically installed between the PV generator and the inverter.

- These SPDs are particularly important in protecting against surges that can arise due to PV panel arcing, inductive loads, or lightning strikes affecting the DC wiring.

- 6. AC SPDs:

- Alternating Current (AC) SPDs are used on the AC side of PV systems, where the inverter connects to the power distribution grid.

- They protect against surges that originate from the grid side or internal AC circuits.

- 7. Modular SPDs:

- These SPDs have replaceable protection modules, which allows for easy maintenance and replacement after a surge event without replacing the entire SPD unit.

- They often come with visual indicators or remote signaling capabilities for status monitoring.

These SPD types can be used individually or in combination to provide layered protection against surges. The specific type(s) deployed in a PV system will depend on the setup of the system, the local environmental conditions, the risk assessment, and compliance with electrical codes and standards.

Grounding is a principal aspect of any photovoltaic system’s design for creating a secure operating environment and contributing to sustainable energy generation. Prioritize professional grounding solutions to prevent potential hazards effectively.

SoloLite PVHub

Model: SP20A1600H

1.Capture Solar Energy

2.Intelligent Distribution

3.Simple Monitoring

4.Customization at Your Fingertips

5.Automatic Updates

Hybrid Solar EV Charger 10-15KWh

Model: JV 10ESSC-EV7, JV 15ESSC-EV7

1.All-in-One Solution

Solar, battery storage, EV charging, power distribution

2.Easy setup, quick results

3.APP with real-time monoitor

MESS Micro Energy Storage System

Model: MESS1000H

1.Versatile Solar Panel Compatibility

2.Easily Upgradable Stackable Battery

3.Seamless Integration with PVHUB

4.Adaptive Charging Modes for Optimal Efficiency

5.Monitor and Manage with Ease

Join the Solar Revolution with SHENZHEN SUNS ENERGY!

Join 80,000+ customers. Explore innovative solar solutions for a greener future. Act now for a brighter tomorrow!